Manufacturing — Romania

OEE Data Analysis and Process Automation Romania

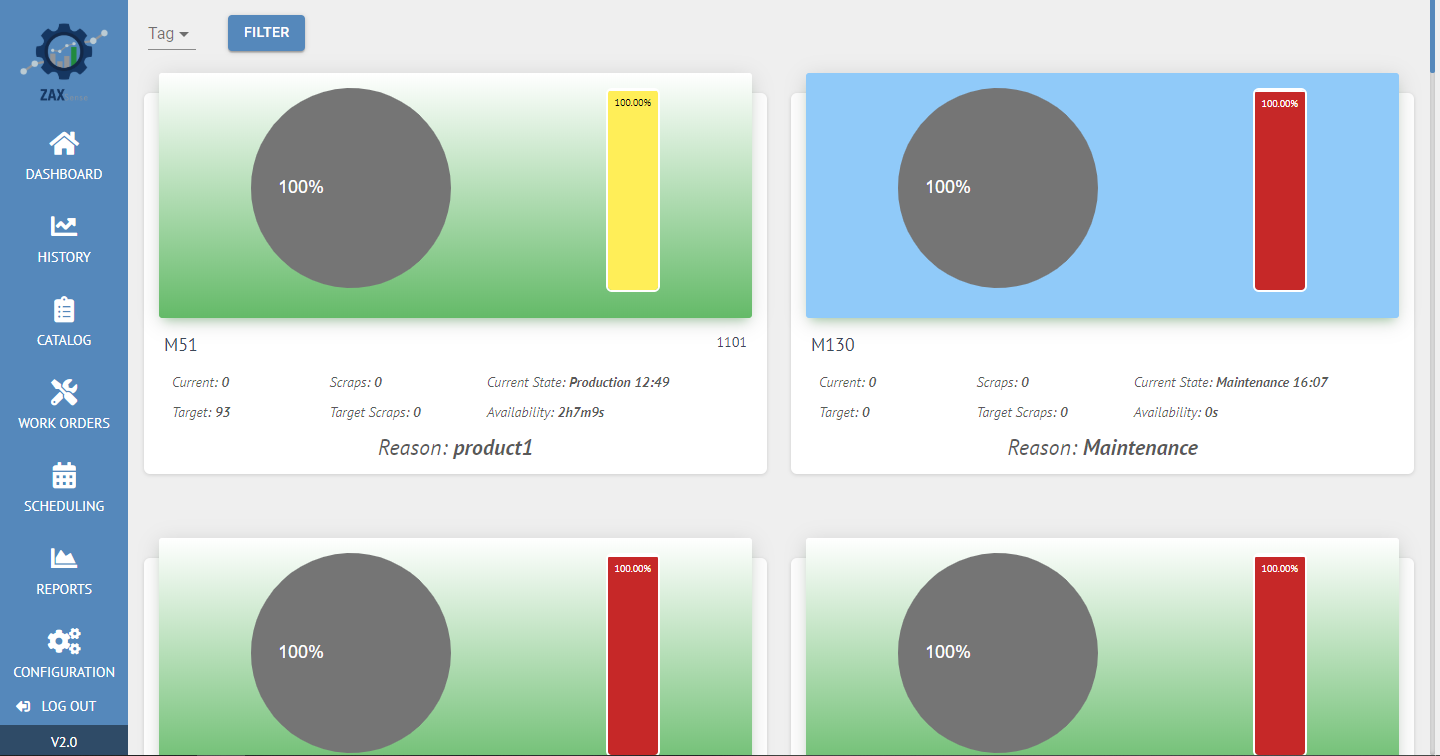

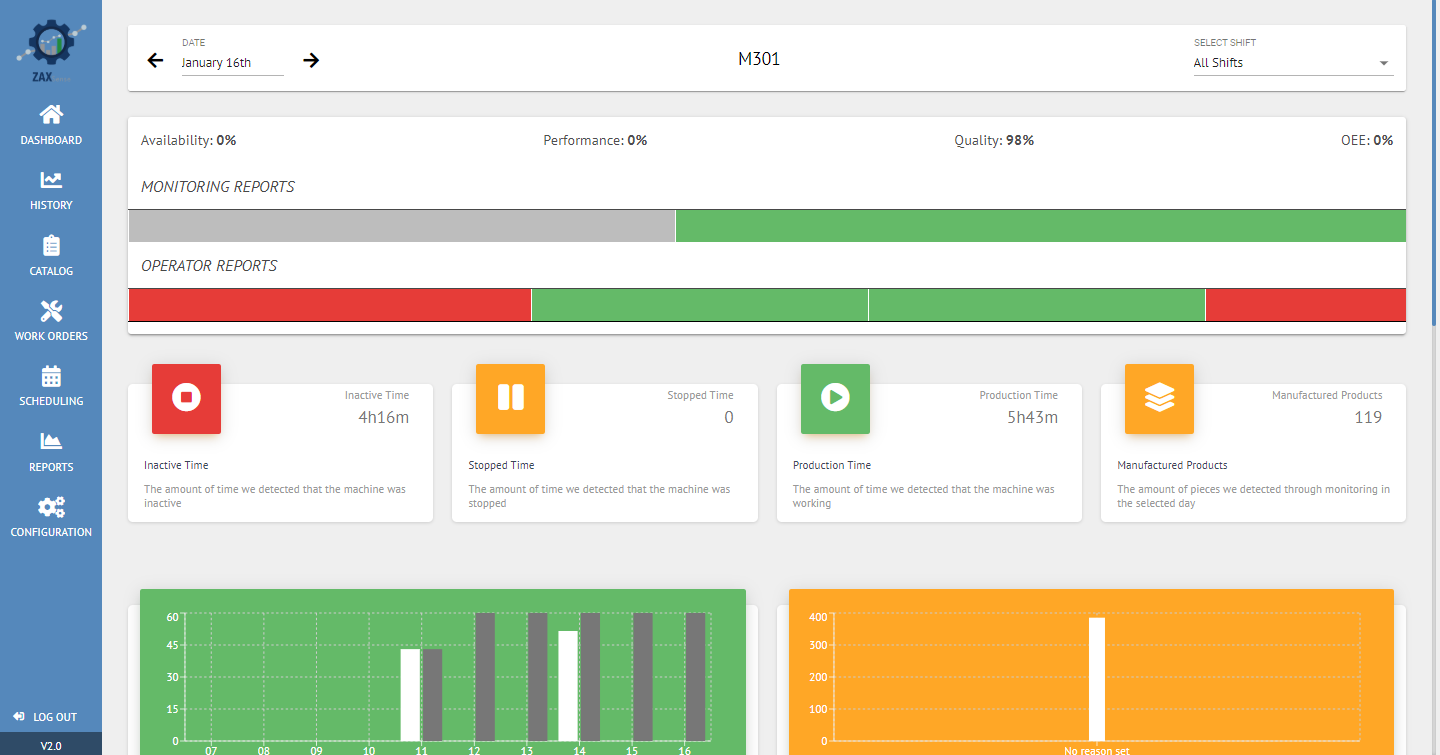

The solution allows view the OEE coefficient in real time and to improve it by having control on all the machines from a manufacture. The solution is formed of 4 services that work and communicate with each other to get data from the factory's machines.

Overview

Solution

MVP, Process Automation, Data Analytics

Duration

20 months, 54 man-months

Team

4 developers

Engagement Model

Dedicated Team

The platform allows the stuff involved in manufacturing to visualize and interpret the state of the machines in the production area in an intuitive dashboard. The solution is formed of 4 services that work and communicate with each other to get data from manufactures, analyze the work cycles of the machines, compare data to count the real OEE. The solution automates the entire process of analyzing data and helps to improve the OEE coefficient.

Built with

Key highlights

Uptime and production increased by more than 20% on average

Over 97% product detection accuracy in real time processing

IoT end node supports up to six connection to various sensors for electrical current, light, magnetic, heat, distance

Easy adaptable to the existing infrastructure of the organization, without requiring any additional changes or investments

Deliverable both in Cloud and On-Premise

From goal to project

Our client is a manufacturing company based in Timisoara, Romania, which aims at automating the entire process of analyzing production data in order to improve the OEE—an industry standard used to evaluate manufacturing productivity.

In order to help our client achieve its goal, we have organized a dedicated team to craft a 3-part solution: the MVP, the process automation platform and complementary data analytics services. More than 14 months have passed since day one, and the work is still in progress.

This project has required the integration of various process-automation-oriented technologies to serve a wide array of uses, ranging from data collection and processing to network and communication management. Additionally, extensive knowledge of technologies of multiple applications was essential—C#, Node.js, React.js, SQL, Redux, Multithreading Application to name the most extensively used ones.

On meeting the challenge

But the real challenge was actually incorporating manufacturing business intelligence into the engineering process of the upcoming solution. And, as agile companies do, we have capitalized on our team strengths to succeed:

The ability to apply and extend our current software development capabilities

The flexibility to adapt to time constraints

The openness to internalize our clients’ internal work process.

Our responsibilities

The solution is comprised of 4 integrated services that communicate with each other in order to gather data from manufacturers, analyze the work cycles of the machines, and ultimately compare data to count the real OEE.

The solution is comprised of 4 integrated services that communicate with each other in order to gather data from manufacturers, analyze the work cycles of the machines, and ultimately compare data to count the real OEE. We have constructed a dedicated team to cover the 5 pillars that lie at the foundation of the solution:

project management, 14 months

Our PM has invested over a year to ensure extensive comprehension of the project requirements in order to plan, together with the team, the best approach to deliver the project on time and at a high quality

front-end development, 14 months

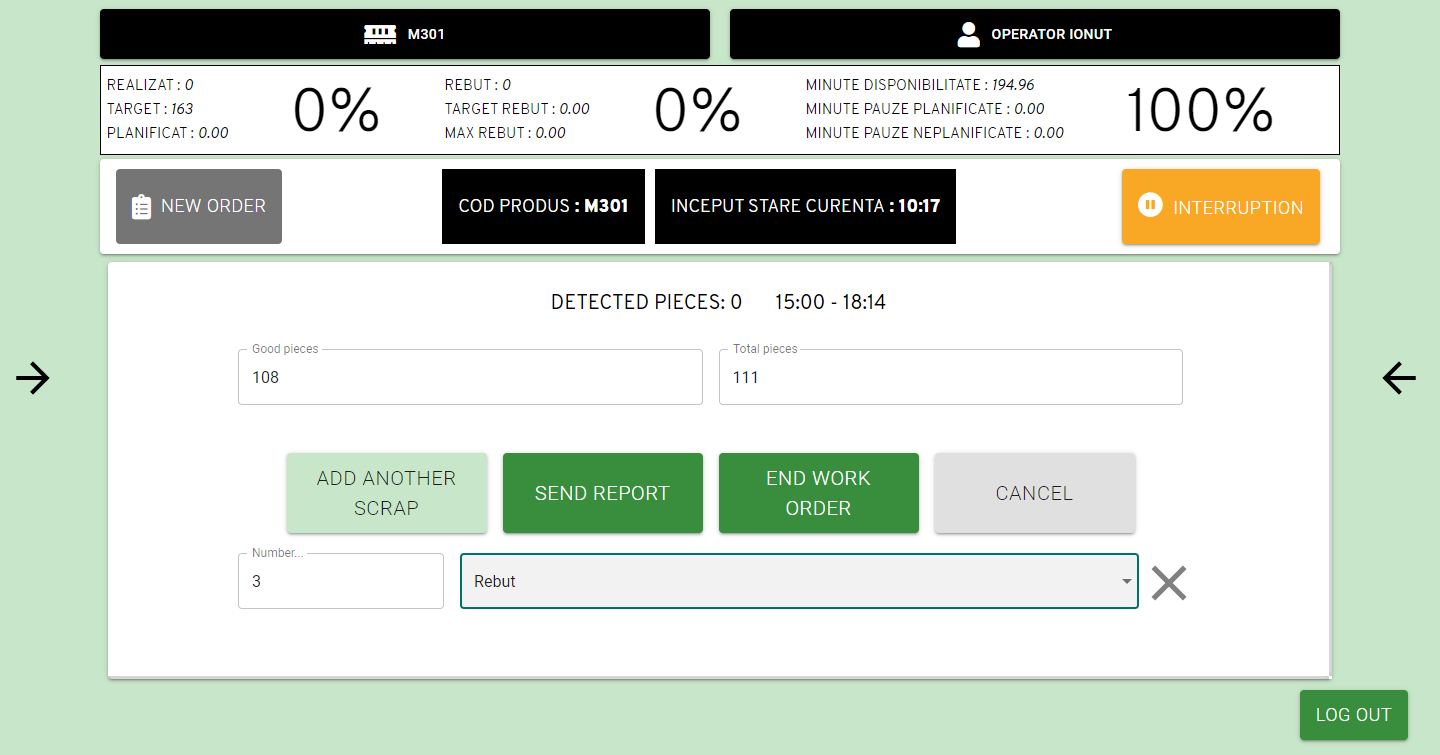

Our front-end developer managed, based on the latest front-end frameworks and Material Design standards, to create a fast and intuitive user interface, custom-made for the client's technical requirements

back-end development, 14 months

Our back-end developer managed to work with though technical specifications and elaborate calculations in order to provide analytical data and improve the client's productivity and overview

DevOps, 3 months

Our DevOps engineer’s major task was to massively automate the deployment process in a smart way—deploy updated versions, on all instances, without impacting the users or misusing development efforts.

Main features

Advanced Search

Enhanced search for precise results.

User Roles

Defines permissions for a group of users to perform a certain set of tasks

Real Time Data Processing

Take input of rapidly changing data and provide output using algorithms

Admin Panel

A dashboard that allows to manage the content and actors of the app

Calea Aradului nr. 1, Birou 1

300088, Timișoara, Timiș

Romania, EU